Product Description

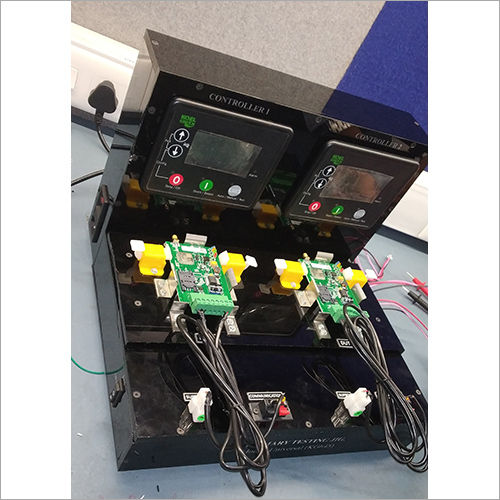

Catering to the needs of our clients, we are involved in manufacturing and supplying best quality range of Primary Functional Dedicated Test Jigs. These are recognized amongst our customers for their features like sturdy construction and robust design. These are designed with modern technology and skills to keep it as per set quality standards at production unit. Our valuable clients can avail these Primary Functional Dedicated Test Jigs from us at cost effective prices.

Versatile Testing for Industrial ReliabilityThis semi-automatic test jig streamlines the testing and inspection of industrial equipment with high precision. Its custom port options, digital indicators, and round die head make it adaptable for a variety of test scenarios. Powder-coated mild steel construction ensures durability, while the bench-mounted design conserves workspace. This jig is a reliable asset for manufacturers conducting regular quality assurance in diverse environments.

User-Friendly Design and Durable ConstructionDesigned for ease of use, the test jig features a clear digital indicator and ergonomic controls. It supports operating temperatures from 0C to 50C, accommodating most industrial settings in India. With a molded forming process and 60 HRC hardness, this jig delivers long-lasting performance, while its powder-coated finish protects it from wear and corrosion.

FAQ's of Primary Functional Dedicated Test Jigs:

Q: How is the Primary Functional Dedicated Test Jig used in industrial settings?

A: This test jig is employed to conduct thorough testing and inspection of industrial equipment. Its semi-automatic operation and digital indicator provide users with accurate results efficiently. Designed for bench mounting, it integrates seamlessly into manufacturing and quality assurance processes.

Q: What ensures the accuracy and reliability of this test jig?

A: Precision is achieved through its tight tolerance of 0.02 mm, robust mild steel construction, and reliable digital display. The custom/test-specific port types and round die head offer adaptability, maximizing both accuracy and convenience for multiple test scenarios.

Q: When should this test jig be utilized during equipment manufacturing?

A: The jig is ideally used during the testing and inspection phases, both before and after assembly, ensuring each component or finished product meets quality standards. Its design enables repeated use throughout the lifespan of your production line.

Q: Where is this test jig typically installed and operated?

A: Designed as a bench-mounted device, the jig fits well in controlled factory or laboratory environments. With a compact footprint (800 x 600 x 400 mm), it optimizes workspace efficiency while maintaining stability during tests.

Q: What is the process for operating the test jig?

A: Operation involves securely mounting the equipment under test, configuring the appropriate port and die head, and setting required parameters via the digital indicator. Testing runs automatically or semi-automatically, and results are displayed digitally for easy analysis.

Q: What benefits does this test jig offer over conventional methods?

A: It improves testing efficiency, enhances accuracy with digital readouts, and reduces manual effort through semi-automatic controls. Its durable build and adaptability to various tests provide long-term cost savings and reliable, consistent quality assurance.

Q: How long is the expected lifespan of this test jig, and what maintenance is required?

A: Engineered for a lifespan of up to 10 years, routine maintenance involves cleaning the powder-coated surfaces, checking electronic components, and occasional calibration to sustain precision. Its robust construction minimizes maintenance demands, ensuring continuous operation.

Mon - Sat 8:00 - 6:30

Mon - Sat 8:00 - 6:30

Mon - Sat 8:00 - 6:30

Mon - Sat 8:00 - 6:30